-

Posts

6 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Posts posted by SirFlamenco

-

-

On 6/23/2020 at 7:08 PM, Zadlo said:

Ad. 1

The main aspect is the hardness of armour material which enables to erode the projectile. For RHA you have some 300 HB, classic HHA has ~500 HB, UHHA has 600-700 HB. Meanwhile worse alumina has ~1400 HV, better one has ~1700 HV, silicon carbide has between 2200 and 2500 HV, meanwhile boron carbide has ~3000 HV. But yeah, boron carbide is not the best material because usually turns into glass during impact. On the other side tungsten carbide used in cores has ~1200 HV.

If armour material has higher hardness that projectile / core material it is better for protection. In case of ceramics shape is another factor while often ceramics placed in plates made for personal protection don't have optimal shape for protection (in reference to armour thickness) but here these shapes are better for multi-hit protection.

Ad. 2

You can do it only with silicon carbide, boron carbide or composite composed of both. Nitrides don't offer such low effective weight. Zirconia is too heavy. While you can't make such a small grain in alumina.

But spall liner from both sides of ceramics helps a lot in lowering armour effective weight. Also the method of effective weight calculation is important to conclude how light the armour can really be.

I actually found the PDF from the company making the stuff, and it's very impressive. There are three main materials. The first one is the nano-ceramics, and they seem to provide good proof that it can resist a lot of hits while having a ME of 4. I still have no clue what they are using though, do you? Next up is the hardened steel, and I think the claim of 30% over ARMOX500Z is realistic and is very likely to be HHS, such as Mars 650 . At the end is MAT 7220 New, and this one I think is insanely good. A titanium-aluminium alloy, that is as light as alumina and cheaper AND very multi-hit resistant. This seems like magic.

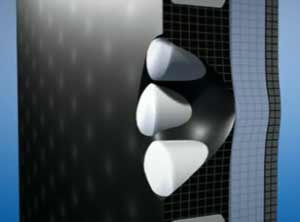

Also, I thought square shapes were the best for weight efficiency? I remember reading somewhere that flexible ceramic panel were heavier due to the weird shape they had to adopt. Can't deny it looks cool though :

-

On 5/21/2018 at 4:22 PM, LostCosmonaut said:

About two sentences later he admits that Arianespace couldn't exist without subsidies from European governments.

"My subsidized jobs program can't compete with SpaceX because they get government contracts!"

"My subsidized jobs program can't compete with SpaceX because they get government contracts!"

Don’t trash the government too much, SpaceX couldn’t have existed without the billions from NASA. It’s FAR from a private sector at this point -

On 6/23/2020 at 3:21 AM, Zadlo said:

What is dimensions of single ceramic 'block' in a composite plate? It is quite important to understand this problem.

I actually figured it out, turns out the CX-950 IC plate was made out of silicon carbide, not alumina. I found out by checking out the only VPAM 10 certified plate made by tencate, the CX-850. I knew this one was already made out of SIC because denmark protection group's level IV plate has the same thickness and weight, and they openly advertise the material. Also, not only is the naming similar, but dividing the CX-950 IC's weight by the CX-850 IC gives exactly 1,5. I also had to account for the corners. Thus, the ME against RHA is exactly 3. It's around 2.4 against HHS. It still seems quite high, but I'm willing to believe it considering tungsten carbide often passes through steel very easily.

On 6/23/2020 at 10:47 AM, SH_MM said:Easy calculation: 160 kg per square meter divided by 32 kg per square meter equals 5. Nano ceramics from IBD Deisenroth (nowadays part of the Rheinmetall Group) provide five times as much protection than steel per the same weight when aiming for STANAGB 4569 level 3 ballistic protection.

This is most likely the best case performance, as marketing material is usually aimed to demonstrate the biggest possible gains in performance. Armor based on "standard ceramics" provides only 2.67 times the protection of RHA in this example, though the term "standard ceramics" is very open for interpretation and likely a weaker configuration to exaggerate the performance gain provided by nano ceramics (it's marketing after all...). I.e. IBD Deisenroth itself claimed that MEXAS (without nano ceramics) could reach a mass efficiency of 3.5 when incorporating a spall liner in the armor array.

Check out my explanation above for the extreme values. Turns out I got the material wrong.

Also, that ceramic in the picture seems very good, even with the marketing. You mentionned Stanag Level 3, which rules out boron carbide since it needs to resist WC. Do you have any ideas what it's made of? -

I want to calculate the weight required to make an armor that can resist 7.62 RUAG SWISS AP, also known as VPAM level 12. I needed a baseline so I took NIJ Level IV and then tried to find the difference of weight so I could get a percentage. The only plate that's still made for this threat is the TenCate CX-950 IC. This plate is 8.93 lbs for a sapi medium and is alumina in-conjonction with soft armor. I then needed to find a Level IV alumina IC, which I found on UARM's website. It's 7.6 lbs, so if we do 8.93/7.6 we get around 1.175, but I put 1.25 considering UARM's plates are often quite heavy. Now that we have 1.25, we can start applying it to silicon carbide and boron carbide. Denmark's group has a level IV silicon carbide plate at 5.95 lbs, so times 1.25 it gives 7.4375. Hesco's boron carbide IV plate is 5.1 lbs, so times 1.25 we get 6.375.

Now, I wanted to know what was the weight for hardened steel. I took MARS 600, which is one of the best armor steel you can get. Using this page, I can easily calculate that you would need about 19mm to stop it. Using a calculator, we know that a full inch sapi medium plate would weight 33.9 lbs. 19mm/25.4mm = 0.748 inch so if we do 0.748*33.9 we get 25.3572 lbs.

The problem is obvious : How is boron carbide 4 times as light as steel? Silicon carbide is 3.4 times as light too? It doesn't make any sense, giving that they are both around 2.2 ME and hardened steel is 1.3 ME, so it should be around 1.7 times heavier for steel. What did I get wrong?

-

Hi everyone, first post here

I stumbled across this video :

It’s super dense polyethylene with a neutral buoyancy core for impact resistance. It weights only 4 pounds, so for weight effiency it’s around 3 times better than ar550 and 4 times better than other ceramics ballistic plates, AND that’s while including the water, which I doubt add any bulletproof capabilities.

Is it just me or does it sound a bit fishy?

Is ceramic 4 times as good as steel? Warning : MATH

in Ballistics Science Discussion

Posted

Here it is https://web.archive.org/web/20111008031621/http://www.ibd-deisenroth-engineering.de/press-coverage.html?file=tl_files%2Fresources%2Fcontent-pdfs%2Fpassiv_protection.pdf