Hisname

-

Posts

144 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Posts posted by Hisname

-

-

-

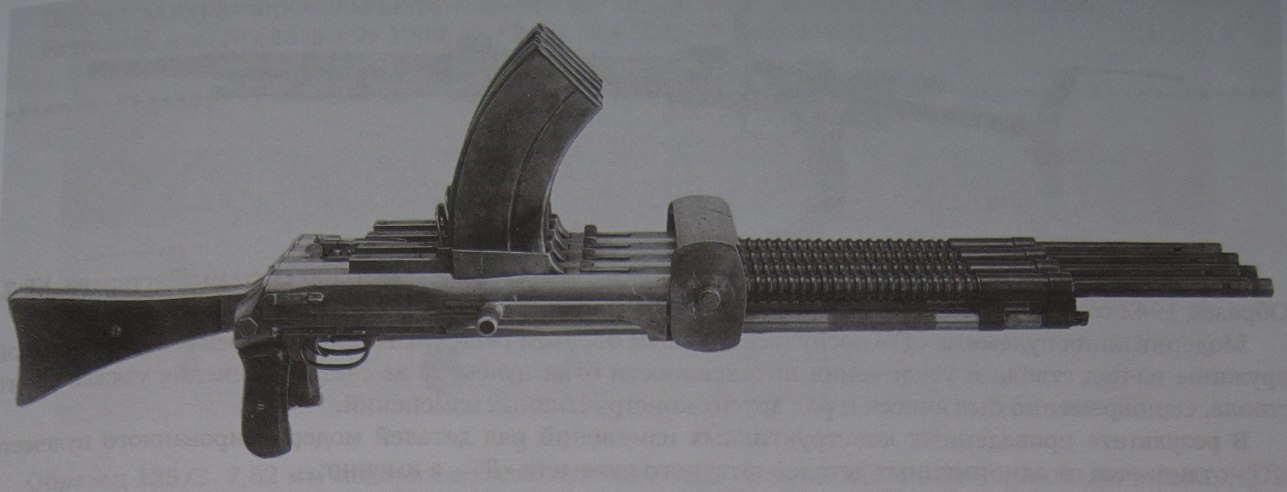

This rifle is made by separatists and is called "Donchanka". The barrel from the heavy machine gun NSV (Kord). Shutter group by the type of anti-tank rifle PTRD.

-

The handle at the gun is pointing down at an angle of 90 degrees. Such weapons are inconvenient to hold in your hand and when firing it will deviate to the sides.

-

Romanian Paratrooper PKM?))

-

Нарукавник - 4 ? ))) "Oversleeve - 4" - ?)) This is a joke? Or the real name of the sight is specially changed in the photo editor to a fictional one?

-

14 hours ago, LoooSeR said:

"Our newest weapon!"

Maybe this is an exhibition of weapons captured from russian soldiers fighting in the Donbass with the separatists?

-

Many people often confuse the appointment of longitudinal grooves on the gun barrel.

In this case, in the machine gun of the PK, longitudinal cuts on the barrel are located near the chamber, where the main heating occurs during the shooting.

And they serve for cooling, because from these longitudinal grooves the area of heat removal increases.

And in this case, on the TSVL-8 rifle (this rifle reminded me of the M2010, with a bolt and barrel from CheyTac M200), the longitudinal grooves are absolutely necessary for the other.

They are needed to lighten the barrel of the rifle and there is nothing more to do with it.

Although, someone believes that these longitudinal grooves on the barrel make the weapon more beautiful, give it a futuristic look.

-

6 minutes ago, Duncan said:

I didn't mean those specific guns, but the engineering as a whole. Let's say a closed bolt automatic rifle that doesn't have a barrel change option. Likely they'd go with a heavy barrel on it for heat mitigation, but would it be better served to be fluted? And if so, are radial flutes the most effective type? Is it just really hard to do, adding much more work and cost?

I'm not that good at understanding the physics of heat-exchange processes, but the designs of modern weapons show that the grooves along the darrel are more effective than the grooves of the sparrow barrel.

To the same, it prevents pollution and facilitates cleaning. If it concerns military models of weapons, the difficulties in manufacturing and the cost go to the back burner.

In the first place is always reliability and efficiency.

-

59 minutes ago, Duncan said:

What is the benefit of radial fluting over fluting down the length of the barrel? Is it just harder to mill out the material?

I did not see any official information about this. Most likely the essence of the unification. The photo shows Degtyarev's experimental multi-barrel machine gun.

The barrel, and many other parts are borrowed from other earlier models of Degtyarev's machine guns.

Degtyarev Aircraft Machine Gun - DA (Degtyaryev aviatsionnyiy). And this is the development of the 1930s.

Then the Soviets did not have an opportunity to accurately calculate the heat transfer of the barrel.

Many things were done on a whim or simply copied from foreign samples. Since DA was an aircraft machine gun, there were no problems with cooling the barrel.

It was well cooled by the flow of incoming air. The experimental multi-barreled machine gun had a supply of cartridges not from a disk store, but from the usual classical one.

A smaller number of cartridges and time to replace the store did not imply a high rate of fire from each barrel separately and should not lead to overheating.

P.S. Yugo M72

-

-

-

-

-

-

-

It looks like a revolver РШ-12.

-

On 5/28/2018 at 9:49 PM, LoooSeR said:

Maybe for a suppressor?

To mount the silencer at the end of the barrel there is a thread that is covered with a cap. This thread is present on both shutter.

I had in mind why one pistol has two shutters of the same marking - .45 ACP. Maybe it's another cartridge or another metal alloy.

-

On 5/28/2018 at 11:13 PM, Sturgeon said:

Caliber conversion, probably.

Both shutters have the same marking .45 ACP. I think the second shutter is for a training or marker cartridge.

-

Please tell me why the pistol needs a second slide and barrel?

-

-

12 hours ago, Collimatrix said:

If it weren't for the text I would say that picture is obviously reversed. Why would the ejection port be on the left?

Please excuse me, but there is very little information on this pistol. This is a pistol for the cartridge .45 ACP; In the manufacture of the modification with a polymer frame, 3D printing technologies were used. The first version of the pistol with an all-metal frame turned out to be too heavy, but it was not completely rejected. It is preserved as a separate modification.

And the photo I came across only one. Here it is entirely:

In the figure with computer graphics, the silencer of the new modification with the lower location of the expansion chamber is most likely represented.

The project of the pistol is being developed in Tula, in TsKIB SOO (ЦКИБ СОО). And it is supervised by its director, Alexei Sorokin.

Data on the beginning of the project began to appear in early 2016. Alas, that's all I know about this pistol.

-

8 hours ago, LoooSeR said:

OTs-122 in .45 ACP

-

40 minutes ago, LoooSeR said:

Question was about gun itself, but it was answered elsewhere.

6х49 ....6х45...6х39mm AK rifle?!!!!

-

20 hours ago, LoooSeR said:

What is this thing?

In my opinion this is a muzzle brake with the functions of a sound moderator.

He hides the flash from the shot, reduces the kickback and withdrawal of the barrel during shooting, and also slightly reduces the sound of the shot.

The Small Arms Thread, Part 8: 2018; ICSR to be replaced by US Army with interim 15mm Revolver Cannon.

in Infantry Tools & Tactics

Posted

In the photo it is very difficult to determine what kind of product is depicted.

In my opinion, the basis was a device for training tank firing, which is inserted into the trunk.

This allows you to save tank shells during training firing and use instead of them 14.5 mm cartridges.

I'm based on one video that I met on the Internet. It shows almost exactly the same rifle.

And judging by the recoil it's not a 23mm cartridge, as they write on many forums, meaning ZU-23-2.