Kal

-

Posts

347 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Posts posted by Kal

-

-

-

-

-

The Nano-Duplex NANOS-BA Steel for Application in Construction of Armors

-

7 hours ago, LoooSeR said:

A fatwa on the journalists' head?

-

General query

If anyone has contacts in commercial casting and heat treating nano bainite please pm me.

I have a consumable product approx 25mm by 50mm that i'm considering transitioning to that variety of production.

-

Thanks, so they are staying at .58 or 0.60 typical levels of C.

-

Just how much carbon is in the polish bainite?

-

So its about double the CEV as Australian Bisalloy UHH 600.

But bainite has some nifty temper resistance properties, so you might be able to weld and stress relieve to above 370C if desired.

-

With some preheat and postheat, can the polish bainite armour provide a manageable weld?

-

21 hours ago, Militarysta said:

If you look carefully, (page 105) you can see they are comparing TT optionTemp. in °C/time in h

ie 210 Celcius for 116 hours is the 210/116

likewise 220 Celcius for 72 hours is 220/72

etc

(this would be faster with higher C, or added Co or Al)

-

1 hour ago, Lord_James said:

After getting some time to read through the article provided by @Militarysta (thank you), I can sorta see how they can pull it off: Manganese and Silicon are both great for making strong steel, manganese increasing the harden-ability of low carbon steels, and silicon also increasing the harden-ability

No, that is not how it works in this case. by far the greatest source of the strength is the fineness of the structure, which is depended upon carbon to drive it, silicon to stabilize it, and soak time at a suitable temperature to let it occur.

This stuff really is the steel matrix from Austempered Ductile Iron, but soaked at around 200 to 300 Celcius, thus the name pizza because it cooks really well at 200 celcius.

(and usefully, a 200Celcius cooked bainite retains its strength to temperature like 500 Celcius, which is different to how QT steels work)

-

-

watch?v=uW9uxb-_2zw

(attempting youtube link)

-

(i would add a youtube of this armour in action, but i cant seem to link youtube)

-

This technique could've been applied to silicon spring steel circa WWII if people had known about it, also it is very suitable for casting, it would've allowed for superior cheap cast turrets fro Soviet or Israeli tanks, but that era is over.

-

https://impact.ref.ac.uk/casestudies/CaseStudy.aspx?Id=24686

it was originally developed from considering gun barrels, austenised steels can have superior properties to QT when the service tempertures go above QT' tempering temperature.

-

http://msmsjec.blogspot.com/2016/08/super-bainite-high-hardness-steel.html

Commercial Super Bainite Steel is low alloy –4.7% (Si Mn Cr Mo) –0.8% C -with no Al, Co, Ti, Ni.

Proof Stress at 0.2% (0.2PS -Rp0.2) is -1673 MPa

Ultimate Tensile Strength (UTS) (RMm) is -2098 MPa

Elongation (El) is 11% Reduction of Area (RA) is5%

Charpy Notch Impact number 5 Joule -based on a 10mm x 10mm specimen at room temperature

Vickers Hardness (HV30) of 690HV30 Brinell (10 mm Ball, 3000 kg load) of 574HBW Rockwell C (20 degree cone 150 kg) of HRC 57

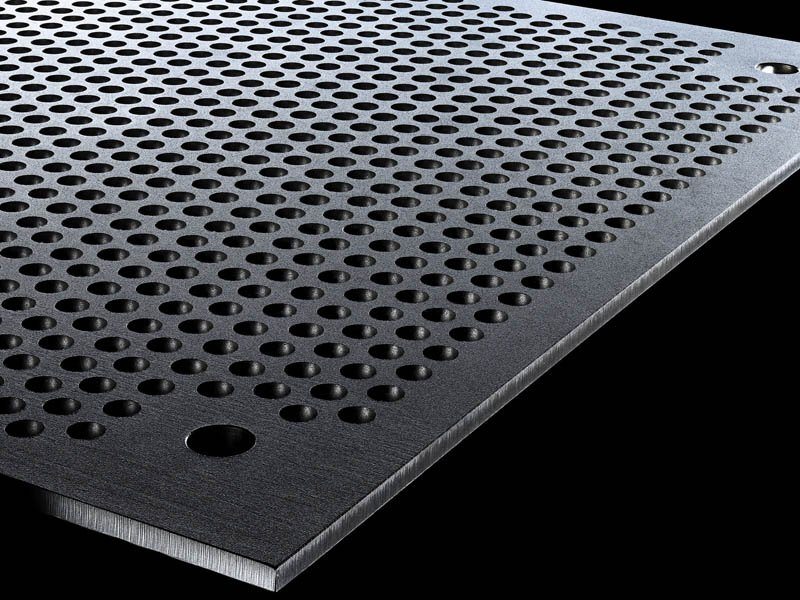

Available in a fixed width of 1250mm up to 5.5m length and two gauges 6.3mm & 8.5mm.

Made as a Pearlite -easy to process

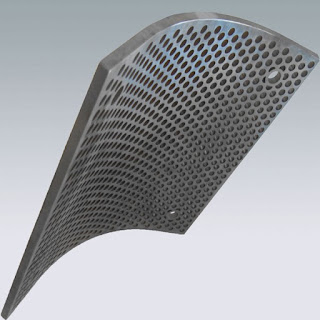

Ballistic mass efficiency of 2.5 in a perforated steel armour system

increasing the Carbon, and or adding Al,Co are the main ways to improve this steel. The key takeaway is that this is a lower cost/ lower performance version

-

This is what also called pizza bainite, super bainite, etc

It is (nothing more, nothing less) than replicating the bainitic matrix of ADI (Austempered Ductile Iron) in a steel.

There are attempts to sell this as armour, for instance PAIVSE 600

https://www.tatasteeleurope.com/en/news/news/2013/2013_lightweight_armour_steel_trade

It is very suitable for making in a perforated state, it can be supplied "soft" then punched/machined/rolled, and then austenised and controlled (slow) cooling for final hardness/strength.

the main problem with this grade of steel, is that it requires a high carbon content (and high silicon) to drive the grain refining process to make it both tough and strong, unfortunately, that also makes not suitable for welding.

Both PAIVSE 600 and it's Polish equivalent seem to have attempted to replicated superbainite, while keeping carbon low enough to be close to/within some other grade of steel, its still not suitable for welding, but its easier to source than purely optimized super bainite, although it not as good ballisticly as higher carbon versions.

This style of steel was kinda accidental discovered by Francisca Caballero in Cambridge UK around the year 2000, by 2006 https://www.phase-trans.msm.cam.ac.uk/2006/ICASS.pdf

https://link.springer.com/article/10.1007/s11665-013-0557-4/tables/2

-

-

FWIW. A modern 50 tonne, 6 wheeled offroad mining vehicle can have a payload of between 80-96 tonne. So a wheeled vehicle with bolt on armour fraction of over 50% - 60% is not a difficult challenge using steel.

How this applies to tracked vehicles? I dont know. But having a 1.5 tonne payload for every tonne of offroad truck seems like a COTS benchmark.

https://elphinstone.com/wp-content/uploads/2019/10/Elphinstone-3900-Series-Specalog.pdf

-

6 hours ago, Serge said:

Does anyone want to get involved ?

Hmmmm

No Burnie Tasmania.

(Elphinestone factory, Sential 2 - land 400 phase 2 contestant)

-

-

Considering the local pollution, i sure hope the foam is mostly harmless, because if it cant handle the foam, it cant handle holland

.jpg/220px-Casspir_(iziko).jpg)

Israeli AFVs

in Mechanized Warfare

Posted

32 years ago? (1987)