SH_MM

-

Posts

1,632 -

Joined

-

Last visited

-

Days Won

155

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Posts posted by SH_MM

-

-

1 hour ago, Kal said:

Its probably was the aussie bits that made the difference for both the thermal signature and the gun calibration.

As you can see in the photos from the Australian trials, there weren't any Aussie bits in regards to FCS/gunner's sight, while the exhaust channel was only present on one of the two Redbacks. The other one "only" was fitted with SolarSigmaShield camouflage system from Rheinmetall Canada (made under license in Australia by CGB Systems).

I wonder if bias is one of the main factor of the different perception. Poles don't really want the Redback (but their MoD wants it) while Australians seem to want Redback (depending on whom you ask...). So maybe similar results are seen as more/less critical by different potential users.

-

-

-

1 hour ago, 2805662 said:

Quite the opposite from what I’ve heard.

The EOS T2000 had a fire control system from EOS. The turret on the Polish test was the Elbit MT30.

They have a common ballistic shell, so telling them apart is tricky. Have to look at the sensors.

"The Redback vehicle that has been tested in Poland is equipped the Redback turret, the same solution offered to the Australian Army in the Land 400 Phase 3 project." according to Defence24.com.

The sensors on the turret are the same, the EOS-made RWS was just removed.

-

-

I believe T2000 is the incorrect designation for the turret (it is the "Redback turret"), but apparently the Polish tests suggest there were accuracy issues during trials of the Redback. Did the Australian military notice similar issues when testing the AS21 Redback?

-

The turret is from John Cockerill. So its not the usual DRDO vaporware.

-

10 minutes ago, Alzoc said:

What's the point of signing agreements when you know they won't be respected anyway...

That's exactly what Germany thinks about French behaviour in the FCAS & MGCS programs.

-

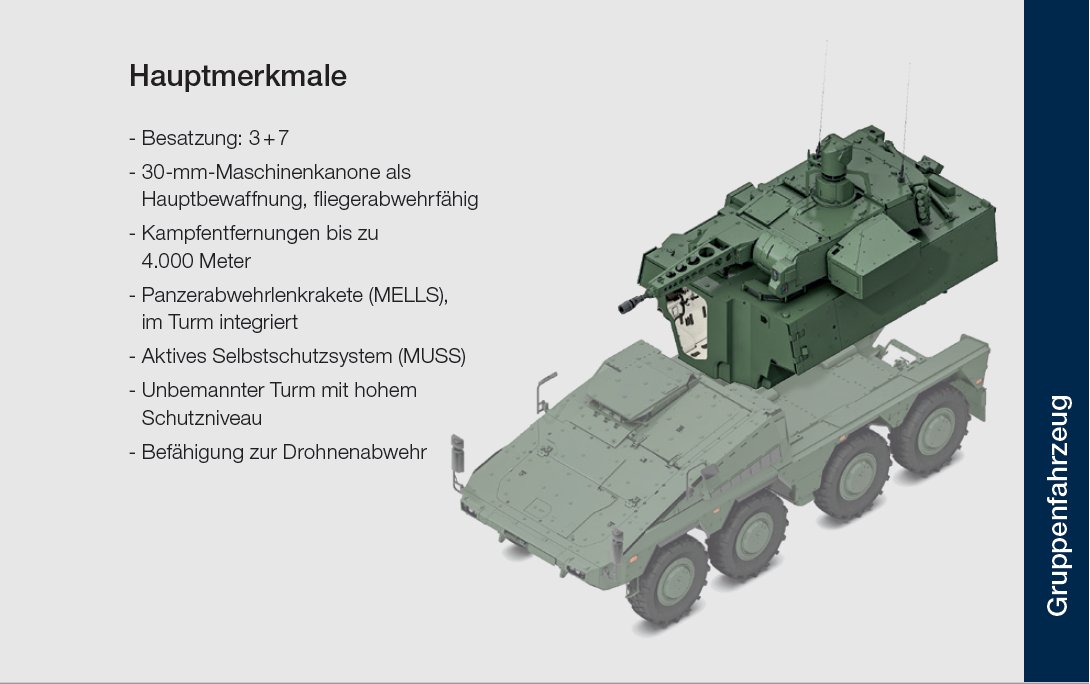

The Pandur 8x8 version ordered by Ghana. Ghana purchased twenty wheeled IFVs from Elbit Systems; the first eleven are based on the Guarani 6×6 and are fitted with a turret from ARES (owned by Elbit), the last nine are GDELS Pandur II assembled by GDELS in Vienna (rather than under license in the Czech Republic) fitted with the UT30 Mk II unmanned turret. No idea whether (and why) Ghana opted for this split or this was decided by Elbit Systems.

-

12 hours ago, Voltzz said:

very nice pictures

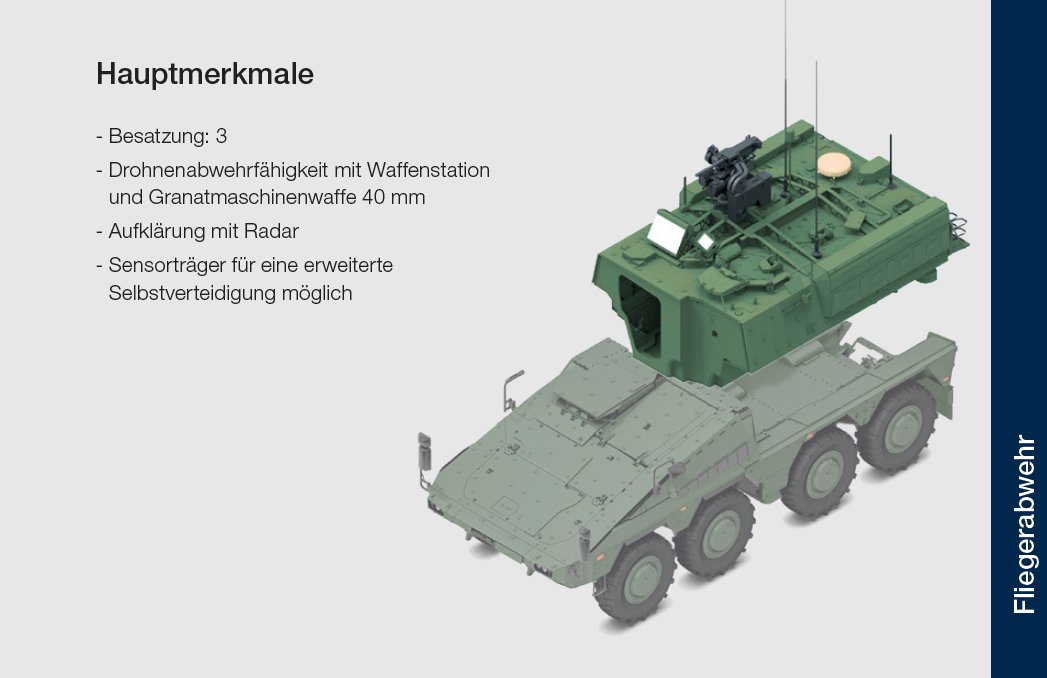

on the "Gruppenfahrzeug" what do they mean by 'capable/capability of drone defence'?

autocannon elevation, sensors,...

KMW has showcased that a software update to the Puma's turret and a RF sensor (direction finder) allows it to engage micro-UAVs. I have posted earlier about this in this topic.

Below is a marketing photo from Eurosatory 2022, showcasing a Dedrone RF360 sensor on a RCT-30 turret mounted on a Boxer. The sensor would detect radio signals as used to control (micro-)UAVs within a 5 kilometres range and determine the direction from which the UAV is approaching. The software updated to the FCS would then allow (probably automatically) tracking the drone and engaging it.

12 hours ago, Voltzz said:and the Anti-tank variant looks very similar to the proposed MBDA/Rheinmetall close-air-defence (NNbS) version.

That is MBDA's Multi-Purpose Combat Vehicle (MPCV) turret, which can be configured for anti-tank use or air-defence use by integrating different missile. It was not proposed by Rheinmetall for the NNbS program, only by MBDA.

- Lord_James, Alzoc and Voltzz

-

3

3

-

-

3 minutes ago, speziale said:

Interesting thing about the STEF, when the soviets tested the 60-105-50 array against the Hetz, they were extremely surprised when the Hetz perforated this array from 2km.

No, Hetz did not defeat the Soviet glacis armor array at 2,000 metres and specifically not the improved armor array (with 60 mm front plate and 50 mm back plate) of the T-72A. It could defeat the original array (80 mm steel, 105 mm STEF, 20 mm steel backplate) at shorter ranges.

-

2 hours ago, speziale said:

I think our interpreation is same in the case of ME. According to your interpretaion 100/0.34~295 kg SiC do you need to reach the same level of protection of 100 kg RHA. But this statement is equal with that 100kg SiC provides you 34 kg RHA equivalent protection (what I said earlier).

The issue here is that the documents do not use the same definition of mass efficiency as we do. The mass efficiency of silicon carbide is not 0.34, it is much higher. The documents use weight coefficients based on a different criteria (probably something that was established back in the Warsaw Pact).

3 hours ago, speziale said:don't get me wrong i don't think armor developers are stupid. I simply do not understand how, based on the given table, it comes out that it is worth using ceramics in the armor.

You are interpreting the table wrong; otherwise every tank would be made out of polyethylene - providing 7 times as much protection as steel per weight and having a "TE" of 1.

3 hours ago, speziale said:based on this, is it possible that in the Leopard2 "D"-tech armor the steel backplate of the ceramic "sandwiches" changed to the "mysterious" wolfram-titanium alloy?

A lot of things are possible, without any more detailed information we can only randomly speculate.

-

9 hours ago, speziale said:

According to my understanding ME efficiency shows the armor efficiency when we keep the plate' thickness constant, and TE efficiency shows the armor efficiency when we keep the late' mass constant.

Take an example:

in the case of SiC a 20mm plate has a 20*0.34=6.8mm protection. In the case of TE efficiency 20*(7.85/3)=52.2mm thick plate has a same mass than a 20mm steel plate. 52.2*0.34~18mm which gives us 18/20=0.9 TE coefficient

No, this isn't correct. The mass efficiency (ME) doesn't say anything about the plate thickness; keeping the plate thickness constant will lead to an incorrect representation of ME. Mass efficiency just shows the efficiency of an armor material/array compared to a reference armor material/array (typically by definition RHA). So if you have an armor material with a ME of 2, then at a constant mass it will provide twice as much protection as the reference material, i.e. even though you only have 100 kilograms of the material, you would need 200 kilograms of steel armor to reach the same level of protection.

As the density of the materials can be different, the thickness of these two materials needed to reach the same protection level can be quite different. E.g. lets assume that the first material (with a ME of 2) is some kind of low-density reinforced plastic with only a fourth of the density of steel. This would not change the ME, but it would mean that you'd need 200 milimetres of this material to reach the same level of protection as provided by a 100 mm thick steel plate (as 200 mm of the material will have the same weight as 50 mm of steel while having a ME of 2, i.e. being twice as effective per weight). So the thickness is completely irrelevant for the ME.

However the above example also shows us the thickness efficiency (TE) of the materials, i.e. the protection provided by an armor material/array for a given thickness compared to a reference material/array (which again by definition is typically RHA). Given that 200 mm of the hypothetical material (something reinforced plastic) provide the same level of protection as 100 mm steel, the TE is 0.5 (half as much protection is provided per thickness).

I am not sure what these excerpts from Russian and Polish documents say, as I can only use a translator to understand them. But it seems that these are not directly ME and TE, but rather coefficients showing how much mass/thickness compared to steel is needed to provide the same level of protection. It is clearly not TE/ME in case of the Polish document, as this lists polyethylene (i.e. simple plastic) in an array with steel plates with a "thickness cofficient" of 7.1 against APFSDS rounds. As steel + polyethylene does not provide ~7 times the protection for a given thickness (nor does it allow reducing armor thickness significantly compared to pure steel), I would rather assume that this means something along the line of "a polyethylene array with preceeding steel plates need to have 7.1 times the thickness to provide the same protection as a simple steel plate".

9 hours ago, speziale said:So, why the hell makes anybody armor out of anything other than steel? Especially if we take into the account that HHS gives us around 1.1 ME/TE coefficient.

The mass efficiency of simple Al2O3 armor with relatively low purity (95%) is in the area 2-2.5 against small arms when place atop of to an aluminium baseplate. This allows a massive weight reduction compared to steel armor. The efficiency of the armor (and the multi-hit capability) can be further increased by using a higher purity ceramic, a higher strength backplate, an elastic backing in the deformation zone behind the ceramic tile (preferably something like Kevlar/Twaron/Dyneema or UHMWPE) and a cover plate/splinter foil.

This means that the ME of Al2O3 can likely exceed 3. For high-performance "nano-ceramics", it can reach up to 5 against small arms. Against APFSDS ammo, the ME will be lower but still decent compared to steel.

9 hours ago, speziale said:Is it possible that use a backing plate and appropriate interlayer material in a structure something like this, improves the ceremics' performance drastically?

It will significantly improve the protection provided by ceramics, yes. It is also a necessity to ensure that the ceramics don't disintegrate after one hit.

-

"MEXAS" is a brand name, it does not reference a specific type of armor. Many different armor solutions made out of different materials (ceramics, NERA, only metal alloys, etc.) were marketed as "MEXAS". IBD developed its first add-on armor systems in 1983; I am not sure if the name "MEXAS" was used already back then. The development of the add-on armor for the Leopard 1 started in 1988.

"MEXAS" is a brand for products purely developed by IBD, though IBD cooperated with various other companies (mainly as provider of technology/licenses). It was made under license in Canada, the US and Sweden. In Canada, DEW Engineering was responsible for production, in Sweden it was Åkers Krutbruk (later acquired by IBD). In case of the US, MEXAS - or rather armor technology from IBD - was at first tested during the 1990s as part of a government-to-government deal between Germany and the United States (with FMC representing the US side and leading parts of the test program). This apparently was a positive campaign, as MEXAS was selected for the Stryker ICV and a license for production was acquired by Simula. Miscommunications between the US side (primarily General Dynamics) and IBD lead to a replacement of the armor supplier, so that DEW Engineering provided the armor for the later Stryker production.

-

-

-

-

-

10 hours ago, Cheburashka said:

Can somebody please give me a quick rundown on frontal sensors starting from the inner side(from the barrel). I believe that the outmost one is the Trophy radar?

ELAWS laser warning receiver made by Elbit Systems, 360° camera system (day/night) and IAI EL/M-2133 radar panels.

-

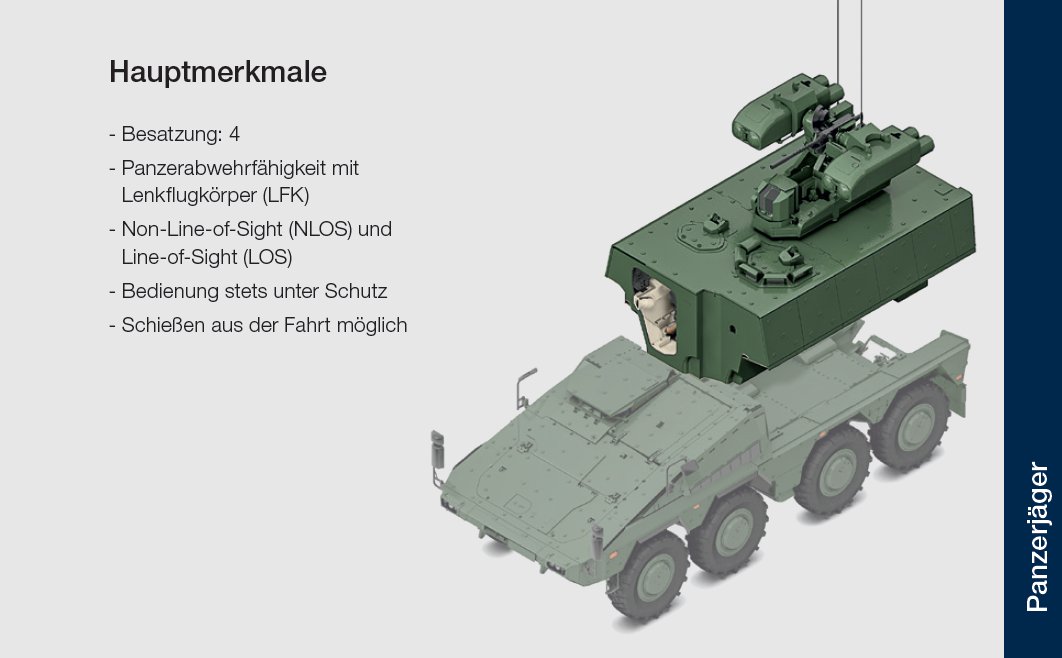

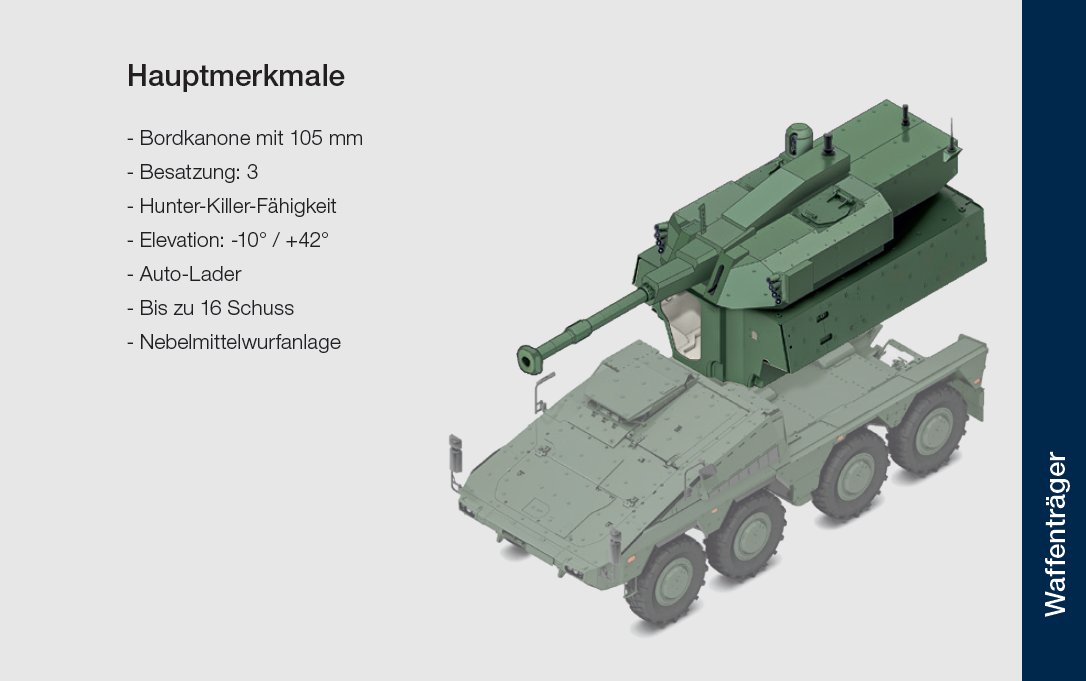

GDELS is developing/offering a whole family of vehicles based on the Pandur EVO.

IFV, anti-tank, SHORAD and mortar carrier variants. More details here: https://esut.de/2022/08/fachbeitraege/ruestung/36452/pandur-evolution-6x6-taktische-und-strategische-mobilitaet-der-extraklasse/

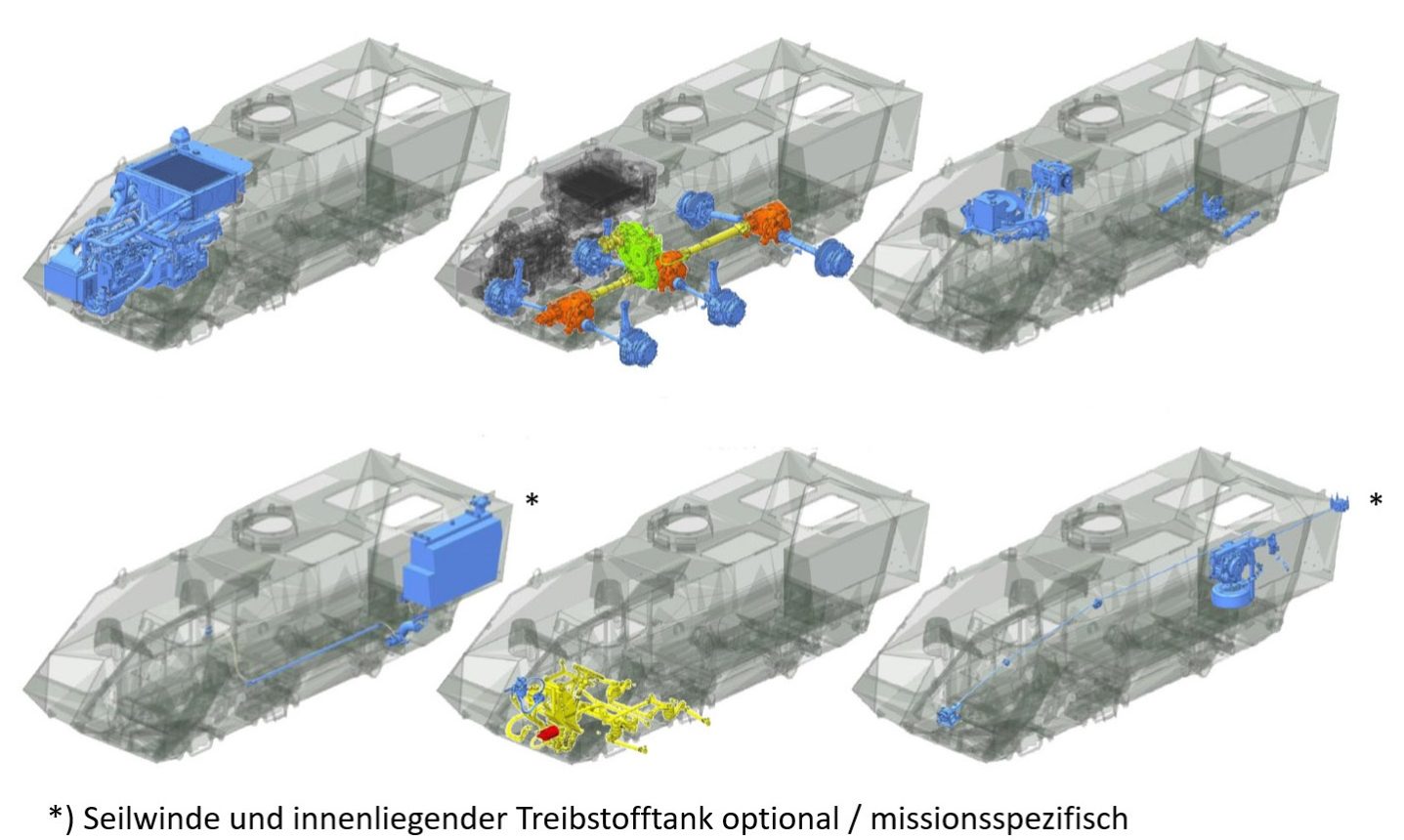

Internal construction details. The basic Pandur EVO doesn't feature fuel tanks under armor, but it is an option (seen on the lower right).

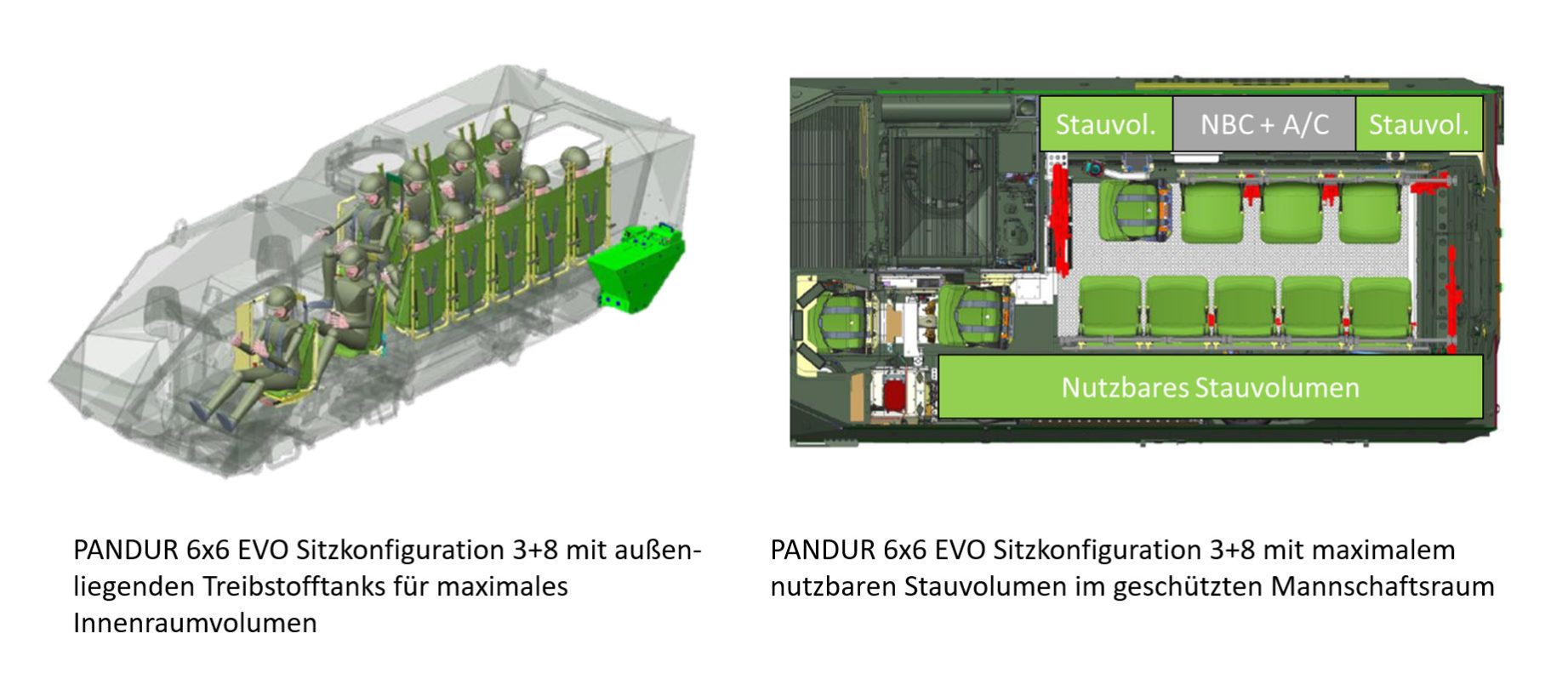

Pandur EVO configured as APC for 3 + 8 men.

Demonstrators for a possible SHORAD system based on Pandur EVO. The SAAB G1X radar is carried on a Pandur EVO production model, the improved design (with integrated headlights) is fitted with an MISTRAL ATLAS RC turret. https://www.militaeraktuell.at/gdels-zeigt-neue-versionen-des-pandur-6x6-evo/

- Clan_Ghost_Bear and Scolopax

-

2

2

-

-

1 hour ago, Lord_James said:

It’s not even 60 tons, of course the armor had to be cut somewhere.

To be fair, Leclerc has "proper" side armor (even more than Leopard 2A4) at a similar weight. The K2 simply was not build with that requirement.

- Laviduce and Lord_James

-

2

2

-

Honestly they could just as well revive Anders. They apparently don't want to buy the AS21 Redback, but the Redback hull and fit it with the ZSSW-30 turret of the Borsuk & latest Rosomak. The same turret could also be integrated into Anders with ease.

Polish procurement is interesting... strongly driven by politics and somewhat erratic. Parts of the Polish defence industry are suing the government for the apparently cancellation of the Wilk program in favor of government-to-government deals.

Land 400 Phase 3: Australian IFV

in Mechanized Warfare

Posted

Unfortunately no. I would be surprised if it is armored, as it is installed on top of the existing armor. It appears to be quite thick though. Ideally it would abe made of something other than steel/metal (something with low thermal conductivity).